Optimize your lithium-ion battery recycling process by using ELIXORE diluents

Sustainable solutions for a greener future

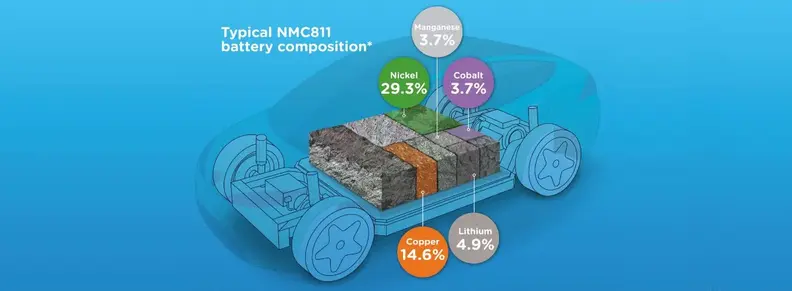

As the number of electric vehicles on the roads is expected to undergo a tenfold increase from 2023 to 20351, so is the number of batteries needed to power them. Recycling end-of-life batteries will become increasingly necessary to sustain this growth without exceedingly tapping on critical earth resources. Metals recovery by hydrometallurgy using solvent extraction has been broadly adopted by the battery recycling industry as it enables both very high metals recovery rates and recovered metals purity.

With a strong track record in metals mining, aliphatic diluents of ELIXORE range have been carefully selected to enhance the safety and efficiency and environmental impact of ore processing by solvent extraction. ELIXORE diluents are ideally suited for extracting valuable metals from black mass issued from lithium-ion batteries pre-treatment, such as2 nickel, cobalt, copper, manganese, lithium, as exemplified in this flowsheet:

1 : IEA - Global EV Outlook 2024

2 : Depending on process design

By introducing ELIXORE BioLife EV 205, TotalEnergies innovates with a sustainable solution meeting the highest standards of environmental responsibility.

Why choose ELIXORE?

Since the processes used in lithium-ion battery recycling are essentially the same as in earth mining, ELIXORE diluents are ideally suited to meet the requirements of this emerging market by providing the following benefits:

Safer working environment

ELIXORE diluents ultra-low aromatic content and low VOC emissions make them safer for operators3 , as evidenced by product labelling and increased occupational exposure limit.

High flashpoints ensure as well safer operations.

Optimal performance

ELIXORE diluents low viscosity and composition facilitate quick phase separation and efficient extraction.

Aliphatic composition reduces oxidative degradation and crud formation, thus extending the service life of the diluents. It also minimizes organic phase entrainment by aqueous phase.

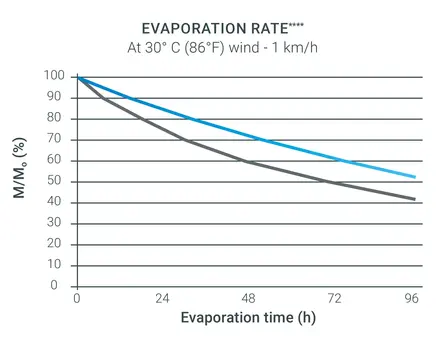

On top of offering reliable performance, narrow boiling range limits evaporative losses and thus diluent consumption.

Environmental benefits

ELIXORE diluents are readily biodegradable according to OECD guidelines, contributing to a reduced environmental footprint.

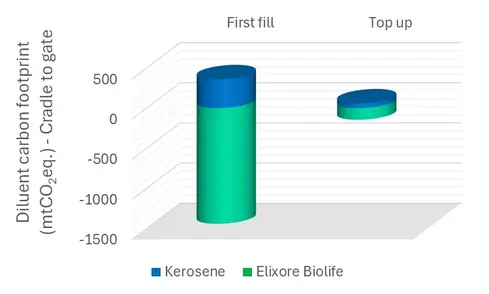

With a cradle-to-gate carbon footprint of -2438 kgCO₂ eq/ton4, ELIXORE BioLife EV 205 enables reduction of the carbon footprint of battery recycling processes owing to its specific bio-sourced feedstock.

3 : Benchmark: high flash point kerosene

4 : Internal Life Cycle Analysis with external review in conformance with ISO 14067

Case study: Carbon footprint reduction5

Considering a 20 ktpa battery waste treatment plant, opting for ELIXORE BioLife EV 205 can enable significant carbon footprint reductions compared to fossil hydrocarbon diluents:

- An estimated 2000 tonnes of CO₂eq for first fill

- An estimated further 300 tonnes CO₂eq annually for top ups

5 Internal study